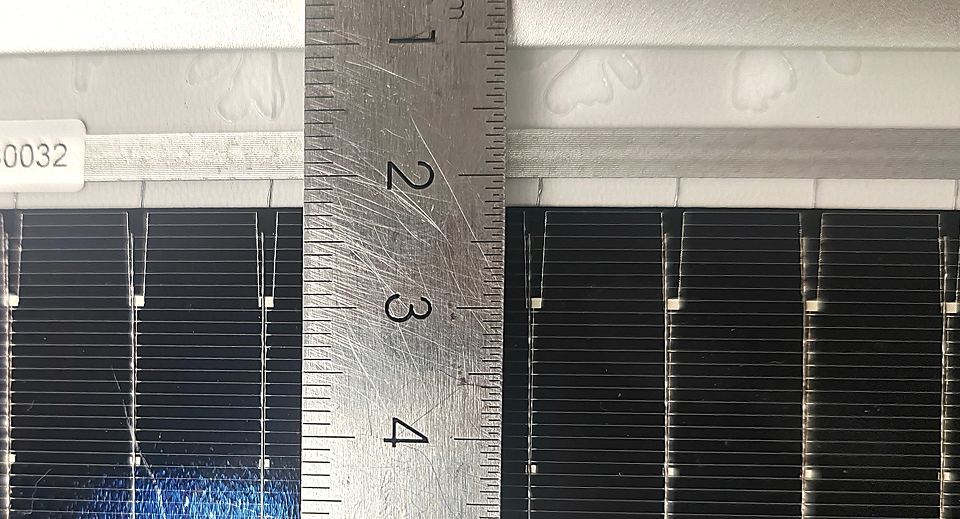

Bubbles can be seen between the frame and the ribbon, reducing the electrical creepage distance and increasing arcing risk.

Key Takeaways

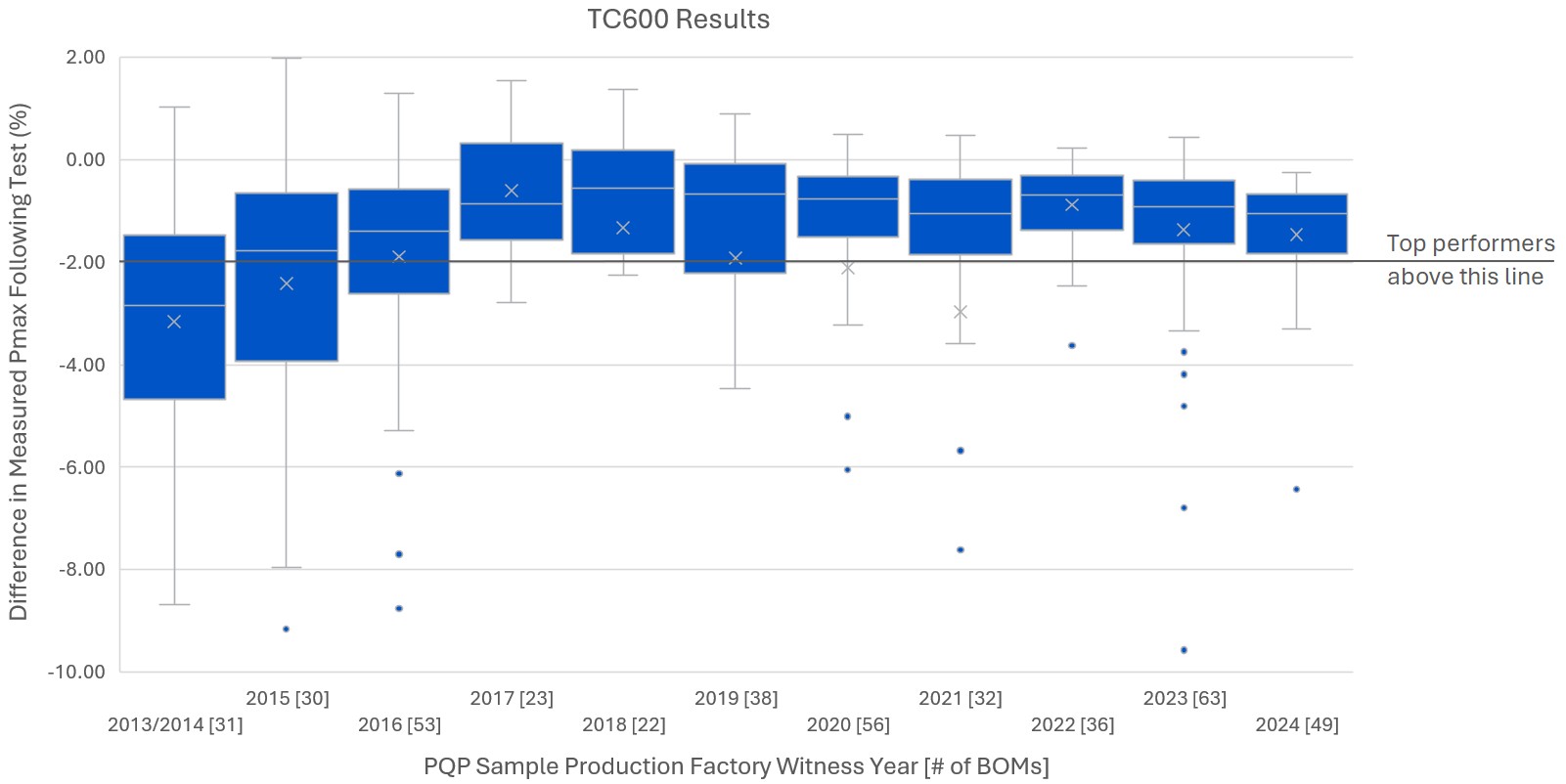

Fewer Top Performers

71% of BOMs tested degraded by < 2% following TC600.

This has decreased from 83% of BOMs degrading by < 2% reported in the 2023 and 2024 Scorecards. While the median degradation following TC was not statistically different from last year, the reduction in BOMs degrading by < 2% is most likely due to some manufacturers trying to reduce silver use in cell metallization to save costs. See the Power Degradation graph below for more.

Cell Technology Influence

TOPCon performed better than PERC. HJT results are mixed.

Over the past year of TC testing, the median degradation rate for TOPCon and PERC was 1.1% and 3.6%, respectively, showing TOPCon technology’s advantage over PERC. Meanwhile, HJT had a lower sample size but a wider range in results, indicating room for improvement for some HJT manufacturers.

Glass//Glass Benefits

Glass//glass performed better than glass//backsheet in TC.

For the 2025 Scorecard dataset, 90% of all glass//glass BOMs tested had < 2% degradation following TC600, versus 0% of glass//backsheet BOMs. This continues the trend reported in the 2024 Scorecard and shows the strong glass//glass advantage in protecting the cells from the asymmetrical thermal stresses present in glass//backsheet modules.

Failures Increase

15% of BOMs experienced one or more failures during TC testing.

32% of manufacturers experienced at least one failure during TC testing, which was up from 20% for the 2024 Scorecard. These included delamination, broken glass, failed bypass diodes and exposed wires. Further, 8% of manufacturers experienced power degradation failures, largely driven by cost reductions in metallization and interconnection schemes. See the Failures page for more.

TC Test Result Spotlight

A recent example of delamination is shown here, with bubbles encroaching from the glass//glass laminate edge (under the frame). While rarely seen at the end production’s visual inspection step, these bubbles can appear following TC and/or DH testing. They create a safety risk by forming a potential electrical path from the module’s current-carrying parts to the grounded frame.

This is a major defect according to IEC 61730 due to the electrical arcing risk it presents. The potential root causes could be various cost cutting measures, including the use of thinner encapsulants, greater laminate edge-pinch following lamination, and/or a reduction in lamination time.