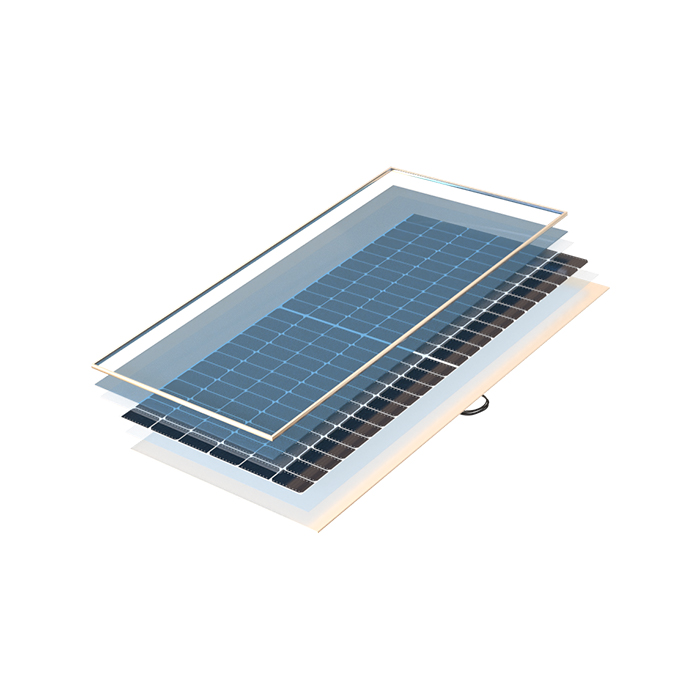

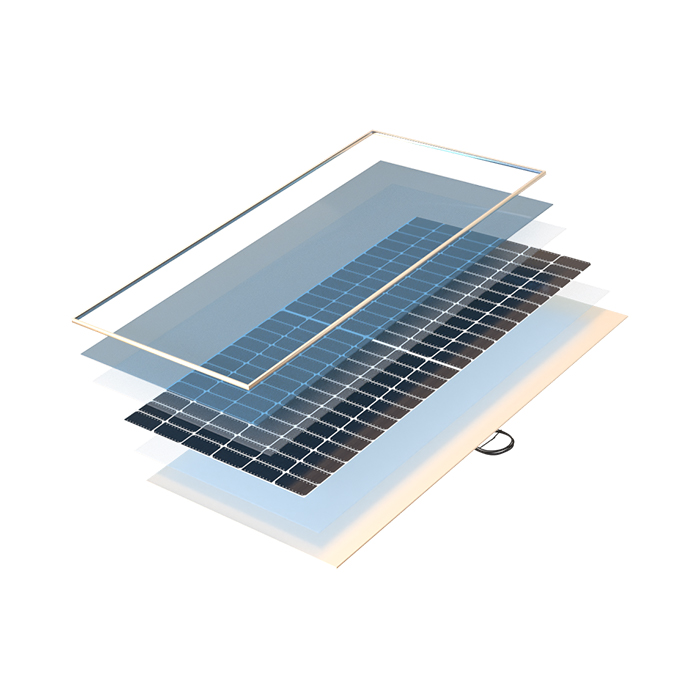

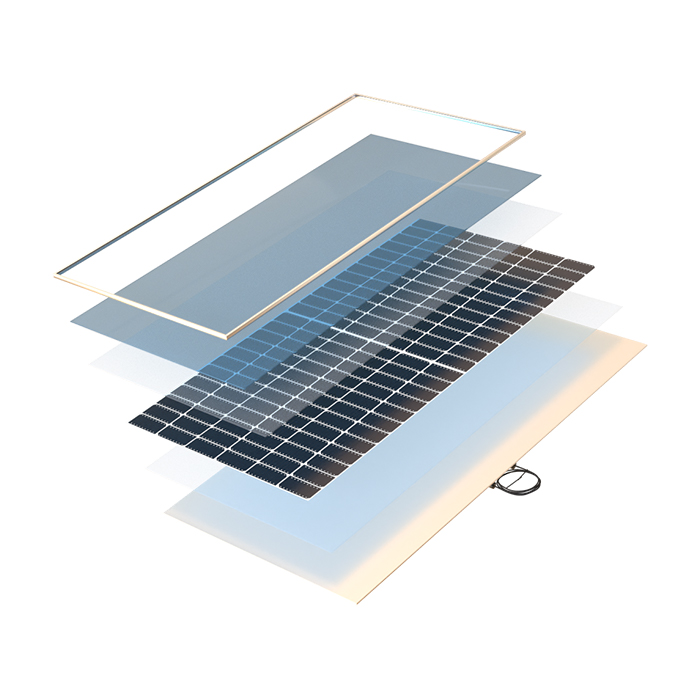

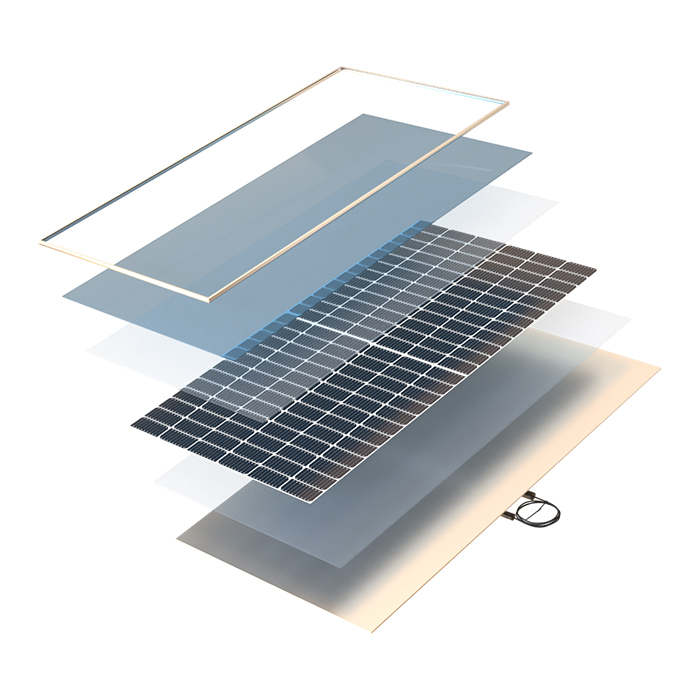

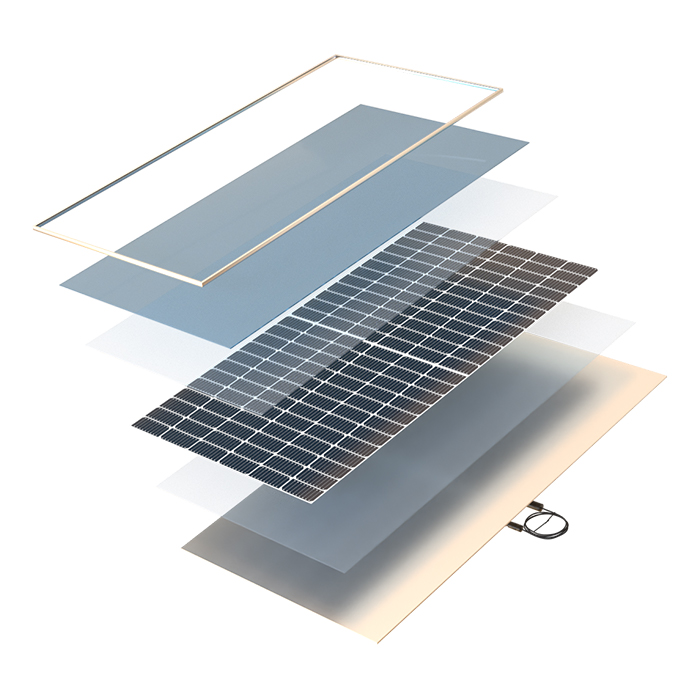

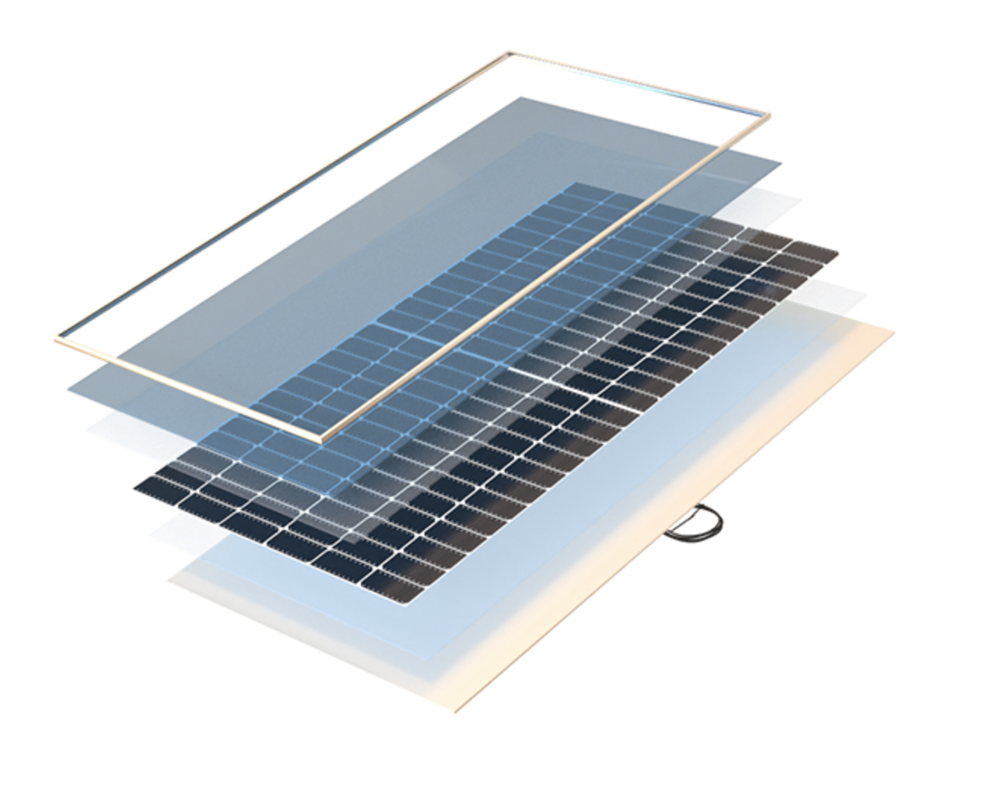

Top Performers are listed in the Scorecard by model type with a unique bill of materials (BOM) designator that represents the specific BOM combination that Kiwa PVEL has tested in our PQP. Scroll to explore the materials of a PV module and click on labels to see how many types of each component were used in the BOMs tested for the 2025 Scorecard.

Go Inside a PV Module

Frame & Adhesives

View DetailsGlass & Glass Coating

View DetailsSolar Cell Layer

View DetailsBacksheet or Rear Glass

View Details

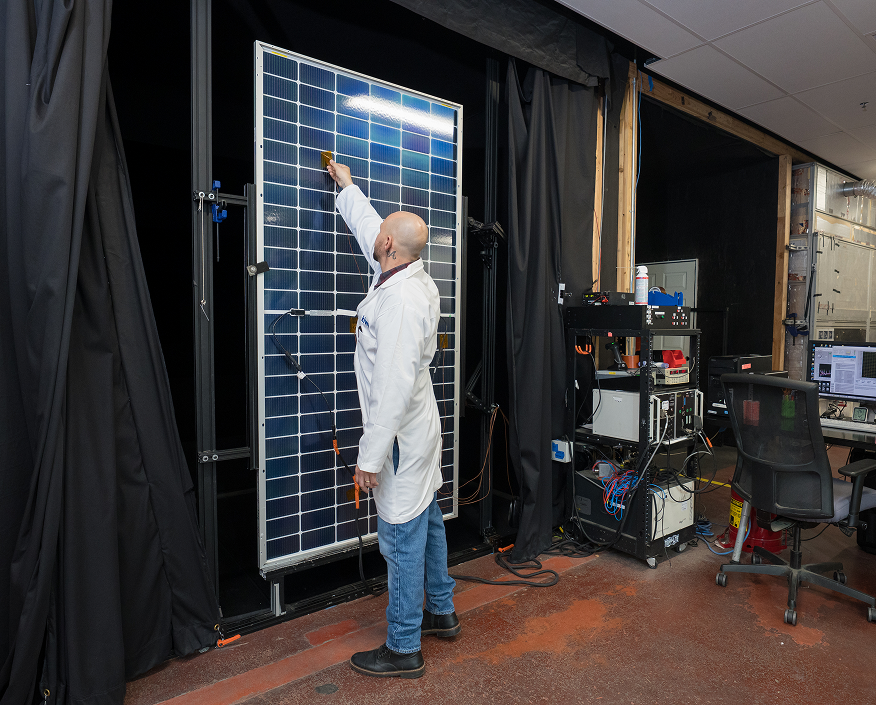

The Importance of PQP Testing

Changes in PV module designs and components can have big impacts to reliability and performance, and the industry’s certification tests are typically not rigorous enough to identify these potential issues. Module warranties often have shortcomings that leave site owners exposed to significant financial losses. Kiwa PVEL’s PV Module PQP is a comprehensive protocol of tests focused on addressing these concerns and helping module buyers achieve better procurement.

Four principles have guided the PQP since it was launched in 2012: the importance of using empirical data instead of assumptions; using standard processes for benchmarking across products; third-party witnessing of the PQP sample production to remove hand-picked, golden samples; and updating the PQP test plan regularly to keep it relevant to current module technology and manufacturing processes.

How BOMs are Scored

To be eligible for the 2025 Scorecard, manufacturers must have:

- Completed the PQP sample production factory witness after October 1, 2023, and, for each BOM shown, have at least one new Top Performer-achieving result that was not included in the 2024 Scorecard.

- Submitted at least two factory-witnessed PV module samples to all PQP reliability tests, as per Kiwa PVEL’s BOM test requirements.

The 2025 PV Module Reliability Scorecard lists Top Performers for seven PQP test categories. To be listed as a Top Performer in a particular test, the modules must not have experienced a wet leakage failure, a ‘major’ defect during visual inspection or a diode failure during that particular test.

- Top Performers for HSS must not have experienced glass breakage during hail testing using 40 mm hail or larger. The actual hail size is shown in the Top Performer list, as well as the BOM glass thickness.

- Top Performers for LID + LETID must have < 1% power degradation when combining the LID and LETID test results.

Not all products or model types are represented in every test. Some of the modules shown are untested variants that have enough BOM similarities to the tested modules that they are included in the Scorecard and shown as “variant”. Manufacturers can choose which BOMs and variants to be listed in the Scorecard, in accordance with Kiwa PVEL’s BOM test requirements.

In some cases, test results for some test categories were not available at the time of Scorecard publication. Kiwa PVEL’s Premium Partners access the detailed PQP results on a quarterly basis rather than waiting for the next Scorecard. Find out more about subscribing here.