Safety Failure

Failure Types

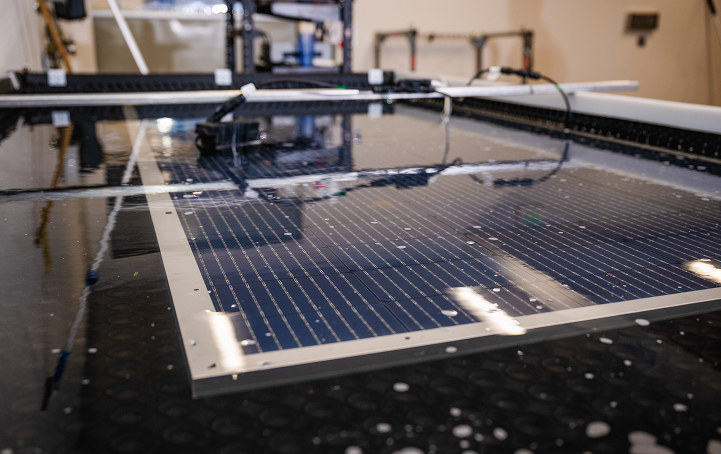

Modules with safety failures may be hazardous to operate in the field. Throughout PQP testing, safe operation is determined via wet leakage testing using the IEC 61215 standard, which evaluates the electrical insulation of the PV module. BOMs not meeting the IEC 61215 minimum requirements for insulation resistance are included in the Scorecard’s failure statistics.

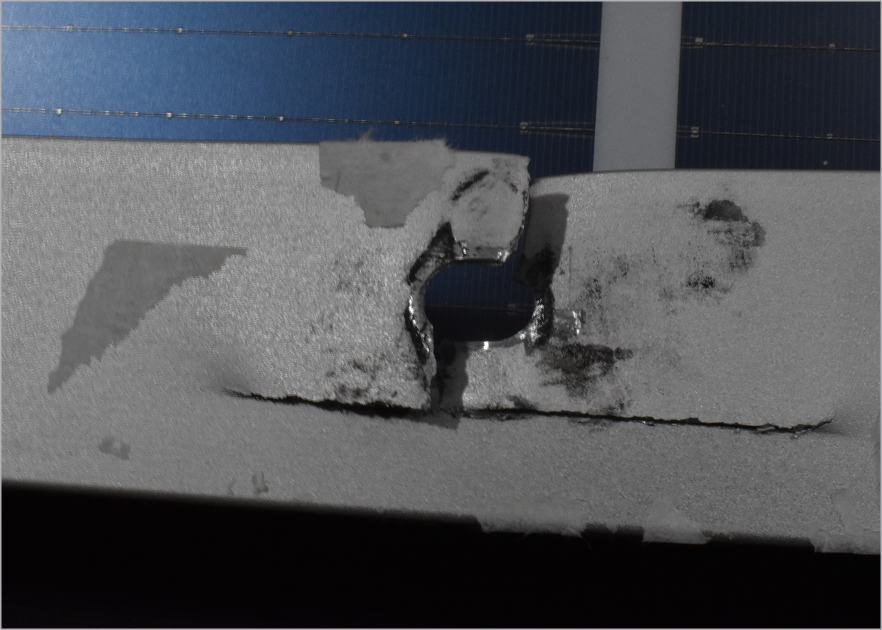

This module failed wet leakage testing following TC200, meaning that it failed an IEC 61215 certification test. Kiwa PVEL’s investigation revealed that the pottant inside the junction box had not cured properly, leading to exposed electrical circuitry inside the junction box. Wet leakage failures traced to the junction box were detected on at least seven different BOMs from different manufacturers within the past year.

Visual Inspection

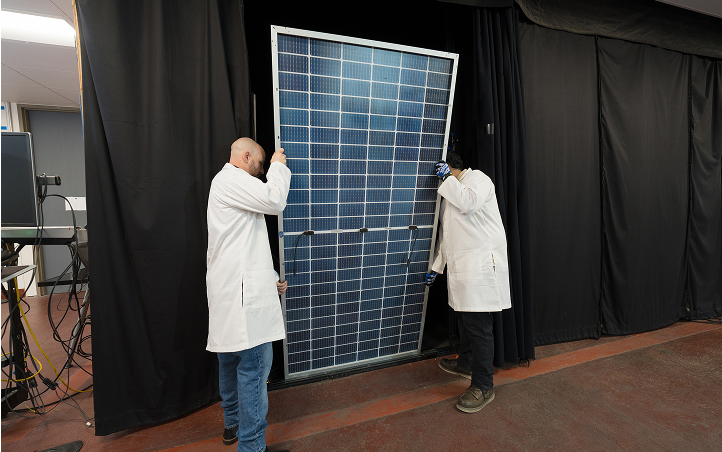

Visual inspections identify issues that cause premature field failure. Modules are examined for delamination, corrosion, broken or cracked surfaces and other ‘major’ defects using the IEC 61215 and IEC 61730 criteria. BOMs exhibiting ‘major’ visual inspection findings are included in the Scorecard’s failure statistics.

This module’s frame experienced a permanently deformed mounting hole during MSS testing. This is considered a ‘major defect’, and is a failure mode seen in the field following wind events. Kiwa PVEL has observed multiple modules with questionable frame durability in the past year, likely a result of cost cutting measures by module manufacturers trying to reduce the amount of aluminium in their frames.

Power Degradation

Modules with power degradation failures may underperform in the field. Although the PQP does not assign specific pass/fail thresholds for degradation, manufacturers may initiate a retest if power loss exceeds their or their customers’ expectations. Retests are clearly noted in PQP reports. BOMs that undergo a retest due to power loss are included in the Scorecard’s failure statistics.

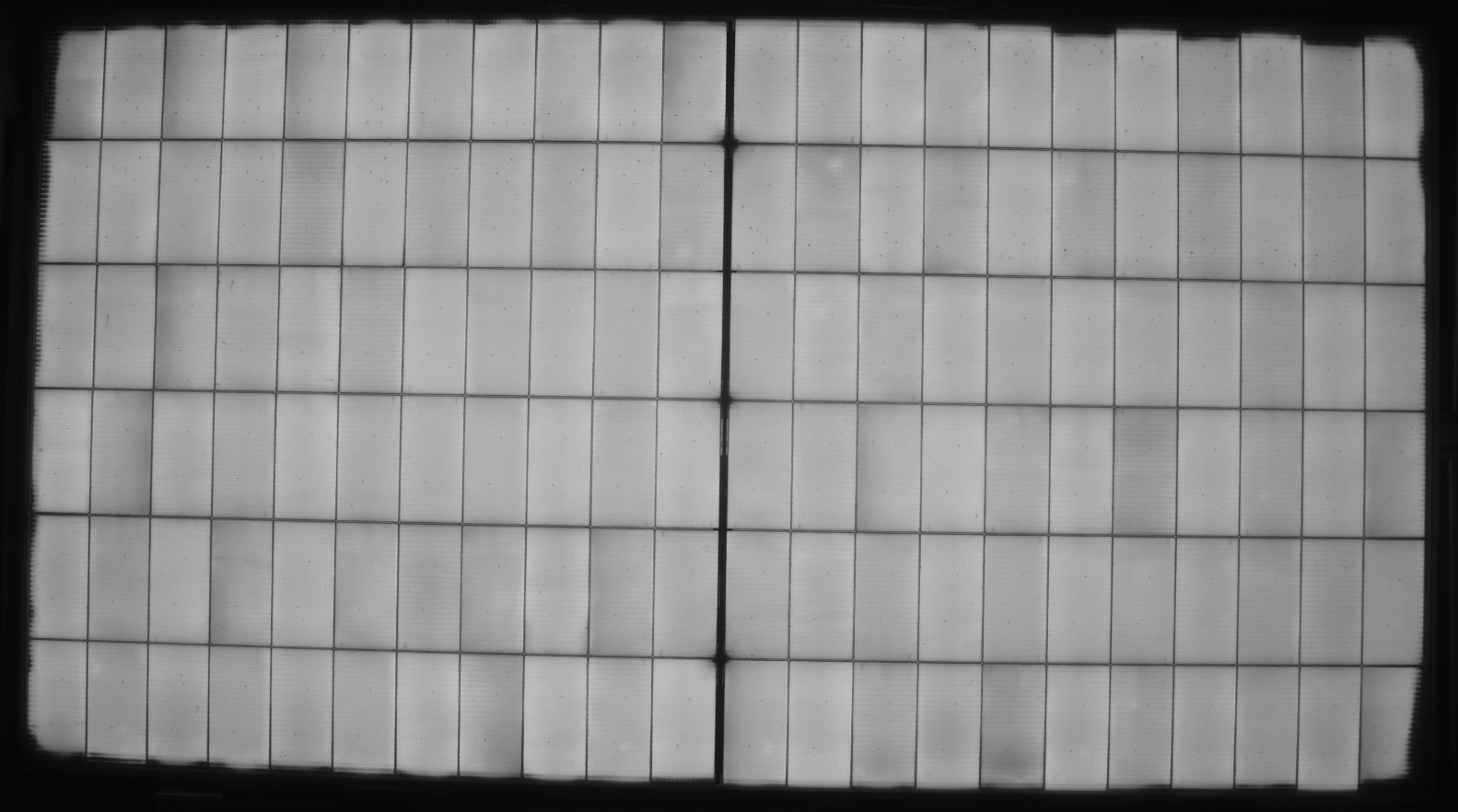

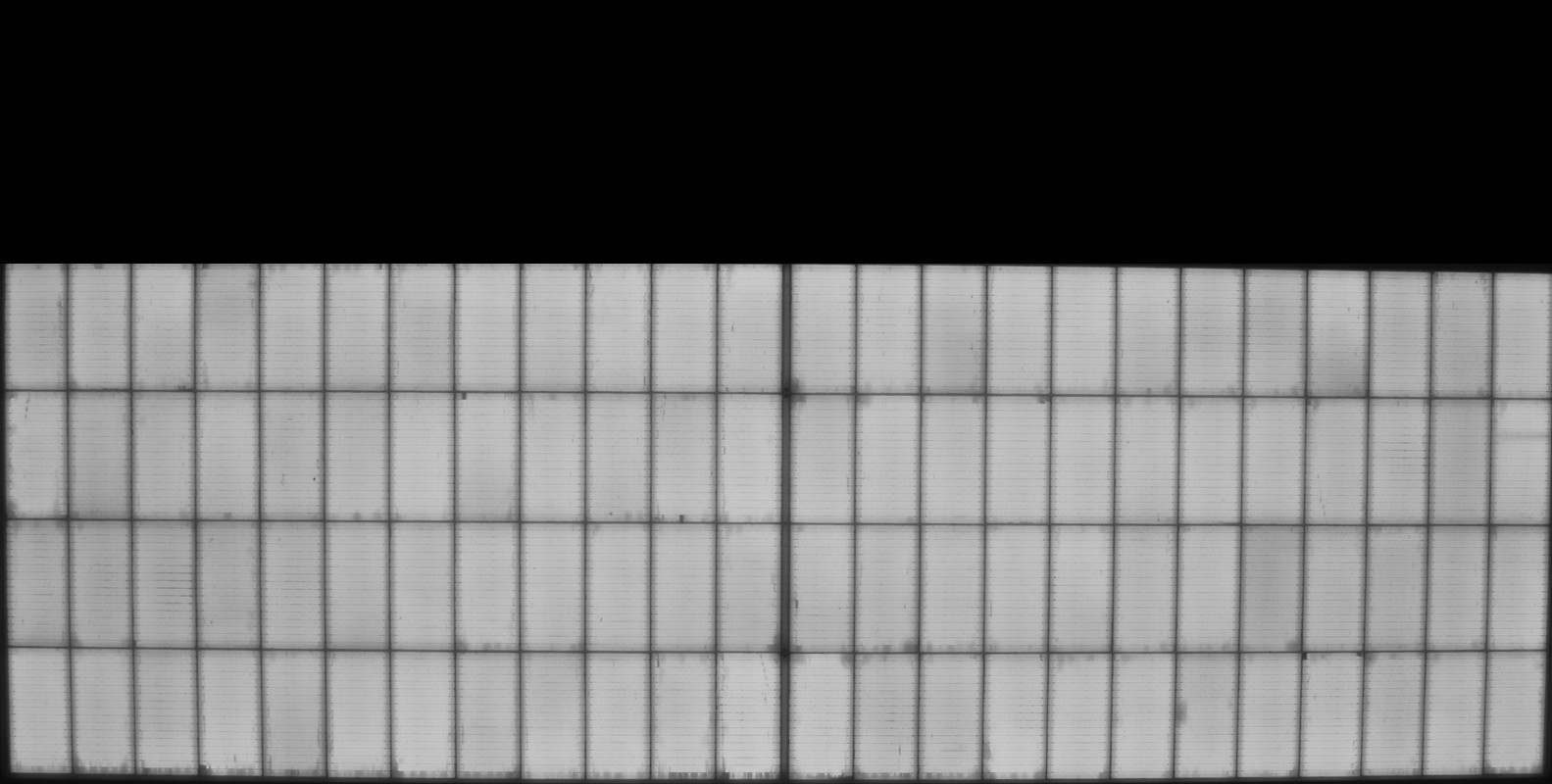

This HJT module degraded 5.5% following DH2000 testing, triggering a retest request by the manufacturer. The power loss was mainly contributed to potential corrosion due to moisture entering the glass//glass laminate along the perimeter and at the junction box holes – as can been seen by the darkening in those areas. 15 manufacturers experienced a power loss related failure in the past year.

Diode

Kiwa PVEL evaluates the functionality of the module’s bypass diodes after TC and MSS testing. A failed bypass diode can no longer protect the module from hot spots, which could lead to fire risk. BOMs with non-functioning diodes in reverse and/or forward bias are included in the Scorecard’s failure statistics.

Following TC600, this module had a short-circuited bypass diode, resulting in 33% power loss. This BOM passed the IEC duration thermal cycling, but experienced catastrophic power loss following the PQP’s thermal cycling test. Two manufacturers had failing bypass diodes in the past year of PQP testing.

Key Takeaways

Module Breakage

Visual inspection was once again the leading failure category.

60% of all failures were detected during visual inspection. The largest source of this was module breakage during MSS testing due to the increase in tracker-mount testing from previous years combined with weaker glass and/or frames. Module breakage during HSS testing also resulted in many failures, which are counted when modules break for both tested hail sizes or when the manufacturer requests an HSS retest.

Power Loss Failures Rise

Power loss failures occur in PID, UVID, TC, DH and MSS.

The percentage of BOMs experiencing a power loss related failure increased to 19%, up from 14% in the 2024 Scorecard. This was largely due to UVID power loss being included as part of the failure statistics this year, which are counted when the module manufacturer requests a UVID retest. The percentage of PID BOMs experiencing a power loss failure remained at approximately 6% for the past three Scorecards.

Safety Failures Persist

Percentage of BOMs experiencing a safety failure stays consistent.

7% of BOMs experienced a wet leakage electrical insulation (or “safety”) failure. This was the same number reported in the 2024 Scorecard, which was down from the 18% reported in the 2023 Scorecard. Most of these failures were traced to the junction box due to poor pottant application and poor sealing around the cables.

Junction Box Failures

One third of manufacturers had one or more junction box related failures.

Kiwa PVEL has highlighted the issue of junction box failures in the past six editions of the Scorecard, yet these failures continue. They include 11% of manufacturers with junction box covers falling off, 8% of manufacturers with loose cables/exposed wires, 8% of manufacturers with bypass diode failures, and 4% of manufacturers with melted/damaged connectors.

PQP Failure Statistics

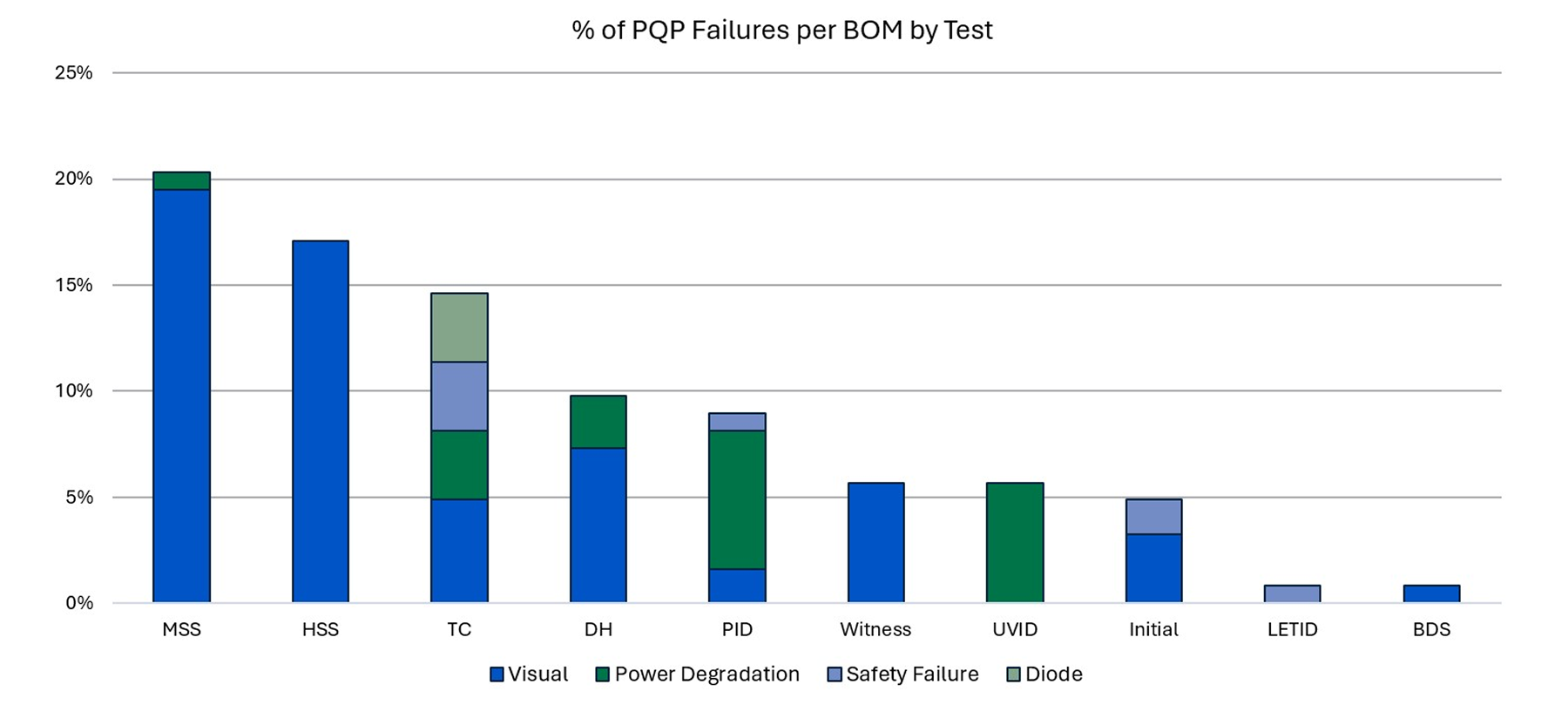

The bar chart displays the percentage of BOMs experiencing at least one failure in each applicable test sequence of the PQP by failure type. Initial failures are those that were detected during characterizations prior to stress-testing. “Witness” failures is a new category for the 2025 Scorecard and was experienced by 11% of manufacturers. These occurred when the manufacturer decided not to ship the modules following the PQP sample production factory witness due to a quality issue.

The most common type of failure is a visual inspection major defect, which accounted for 60% of all failures. This is followed by power degradation failures, at 21%.

The percentage of PQP failures per BOM by test sequence.

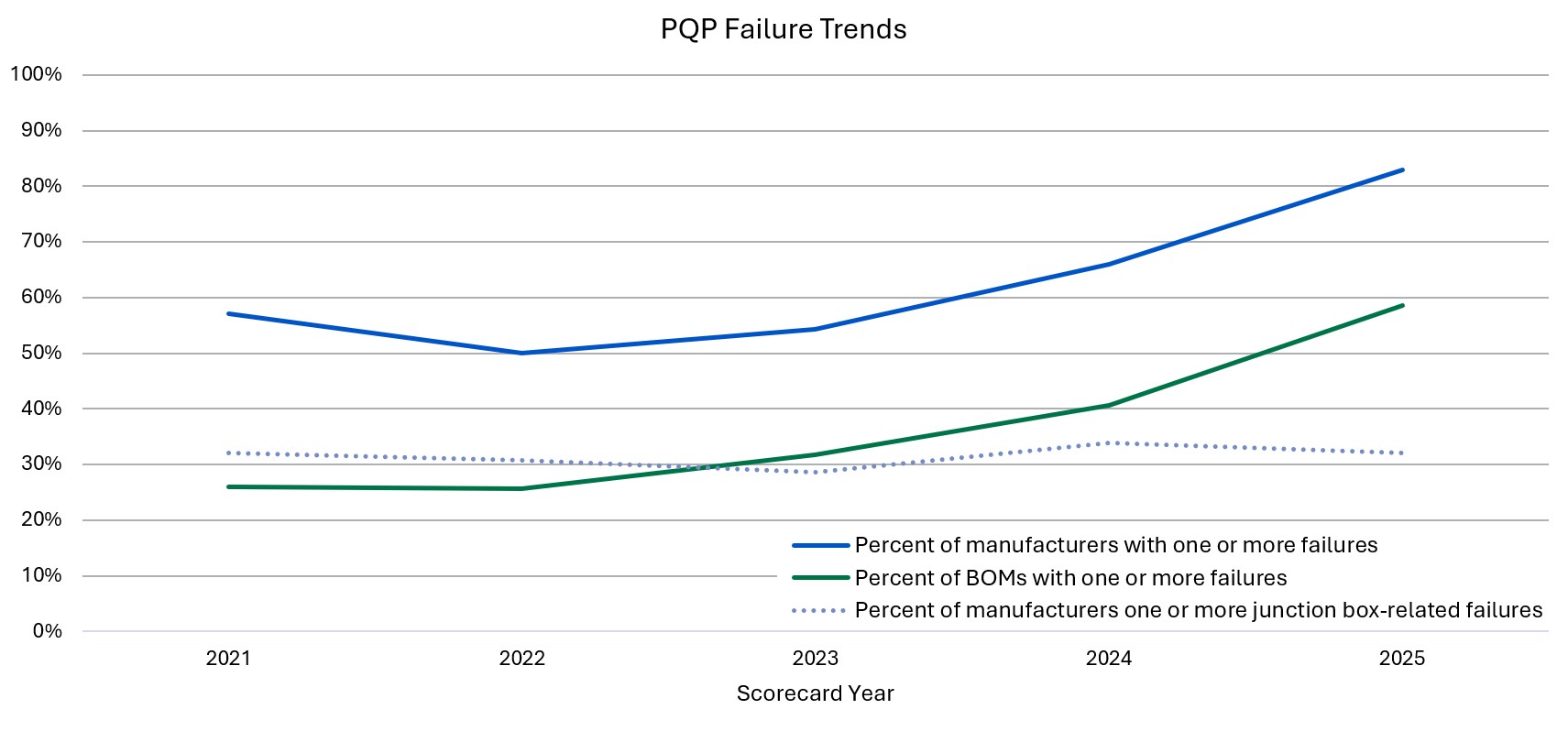

New for the 2025 Scorecard, the history of reported failures across the past five Scorecards has been included in the line graph below. This clearly shows that the percentage of manufacturers and BOMs experiencing at least one failure has been steadily rising, while the percentage of manufacturers experiencing one or more junction box-related failure remains consistently high.

PQP failure rates as reported in past Scorecards.