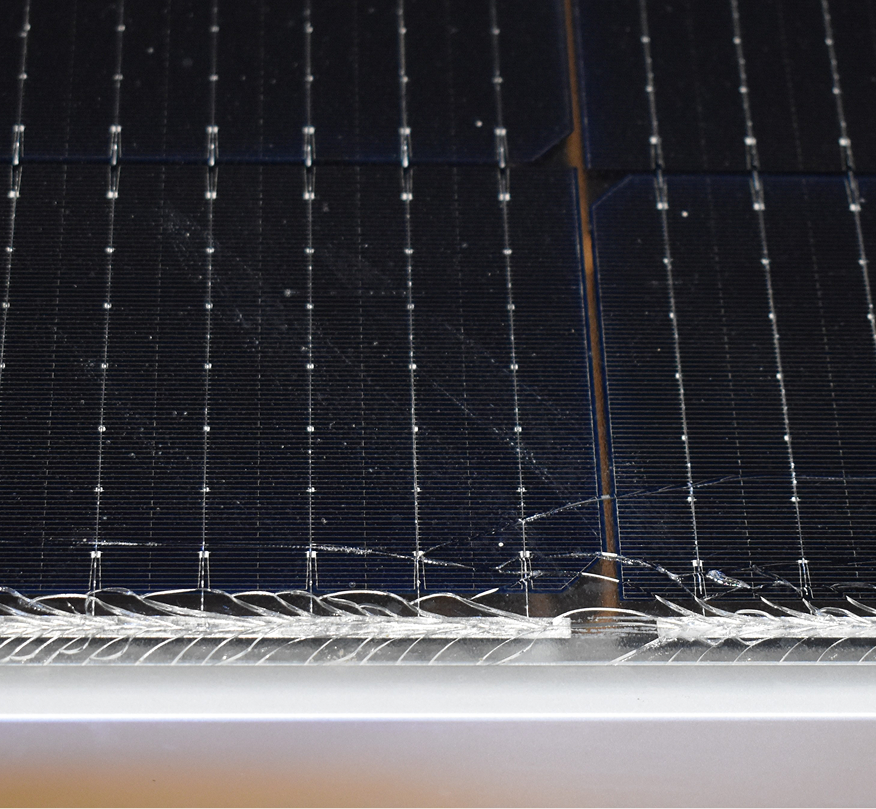

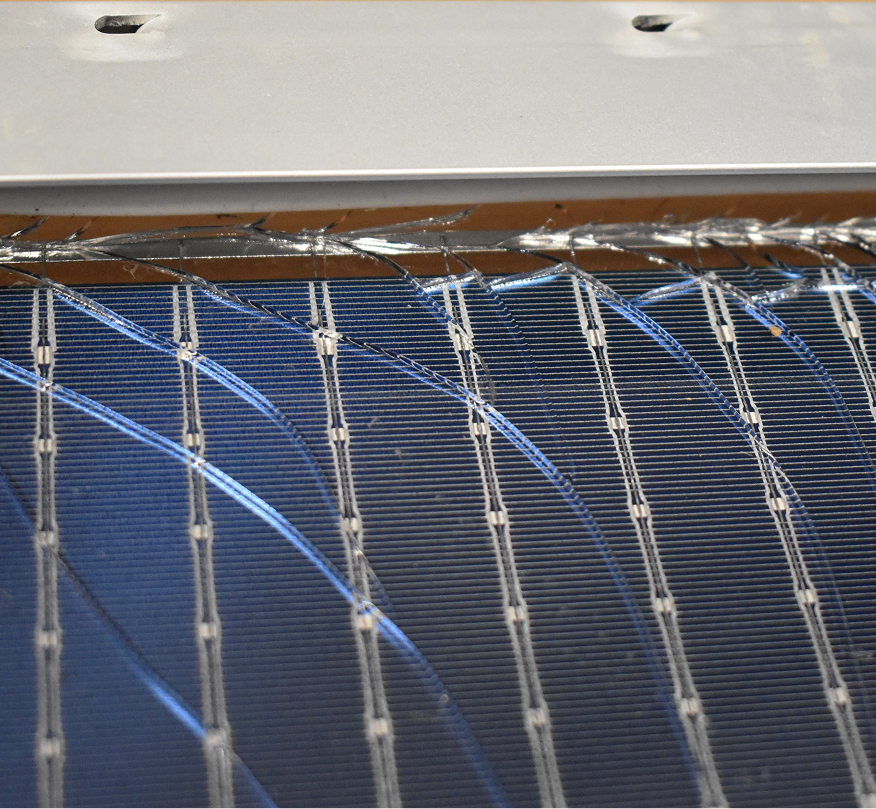

Glass cracking stemming from the module busbars in glass//glass modules can be prevented with thicker encapsulant and/or changes to lamination recipe.

Key Takeaways

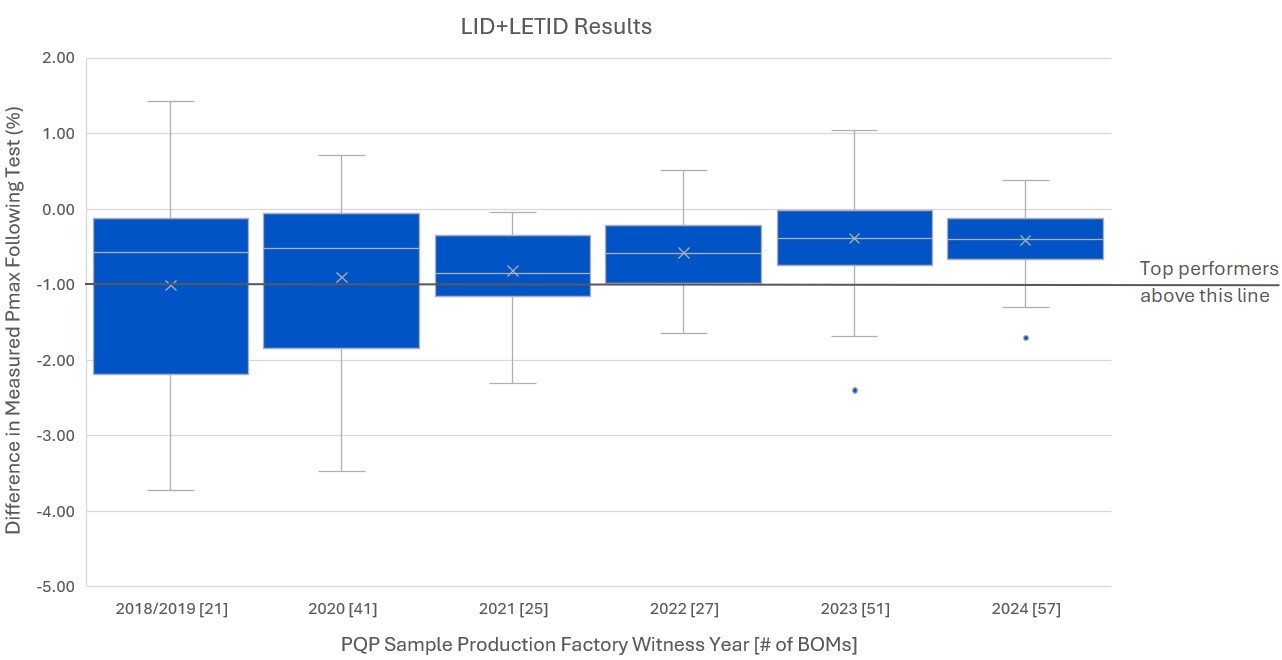

Minimal Degradation

93% of BOMs tested had < 1% power loss in the combined LID plus LETID.

This is slightly down from the 96% of BOMs with < 1% reported in the 2024 Scorecard, but the median and average results were virtually identical for BOMs produced in 2023 and 2024. LID and LETID remain at historic lows. See the Power Degradation graph below for more.

LID by Technology

Low LID values across cell technologies, with statistically no differences.

The median LID power loss for 2025 Scorecard eligible BOMs was 0.4% for TOPCon, 0.4% for PERC, and 0.3% for HJT. The average power loss was 0.4% for TOPCon, 0.3% for PERC and 0.4% for HJT. While the sample sizes were lower for PERC and HJT, the LID results were statistically the same regardless of cell technologies.

LETID by Technology

Similar to LID, very little difference is seen in LETID results across cell technologies.

The median LETID power loss for 2025 Scorecard eligible BOMs was 0.0% for TOPCon, 0.0% for PERC, and 0.2% for HJT. The average power loss was 0.1% for TOPCon, 0.2% for PERC and 0.1% for HJT. A strong overlap in the range of results for all three cell technologies was also observed.

Initial Failures Decrease

Pre-stress testing failures drop from a high in the 2024 Scorecard.

5% of BOMs experienced one or more pre-stress testing failures, down from 11% in the 2024 Scorecard. In the worst example of pre-stress testing failure, one BOM had multiple broken glass modules during LID testing (see the Test Result Spotlight below). Initial safety failures, missing junction box lids and delamination also occurred. See the Failures page for more.

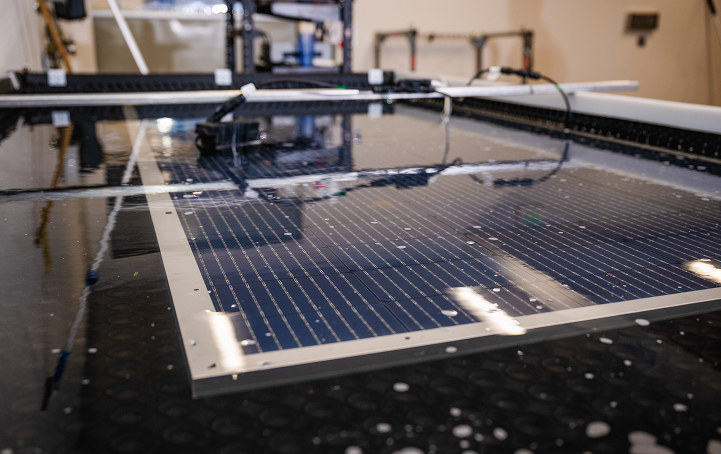

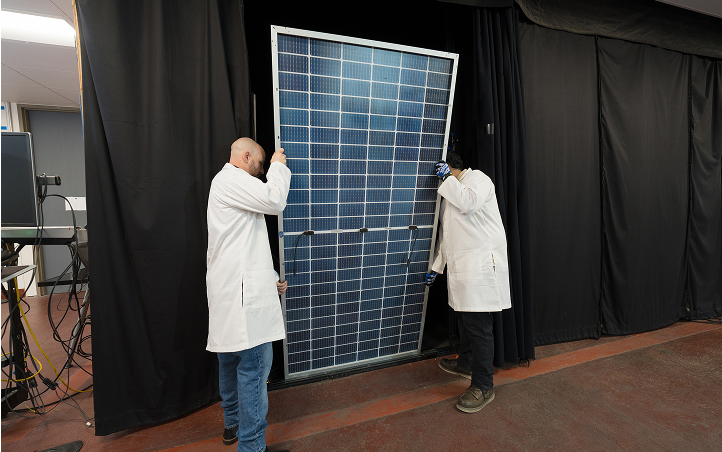

Test Result Spotlight

Glass//glass modules experiencing spontaneous glass breakage is the most significant reliability issue affecting today’s PV modules. Kiwa PVEL is aware of it occurring in multiple countries, with multiple module model types, mounted to multiple tracker/racking solutions. While this is not a failure mode often associated with LID and LETID testing, Kiwa PVEL was surprised to recently see six of 20 modules from one BOM showing a unique glass breakage pattern following outdoor LID. The cracks along the busbars indicate a lack of encapsulant along the laminate edges, leading to edge-pinch induced stress concentration points between the metal busbar and the glass surface.