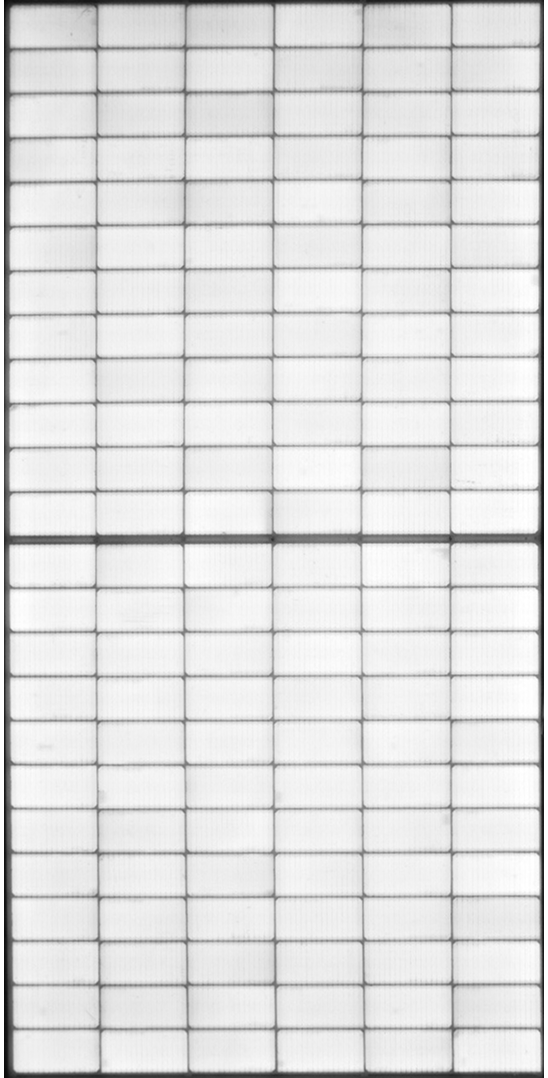

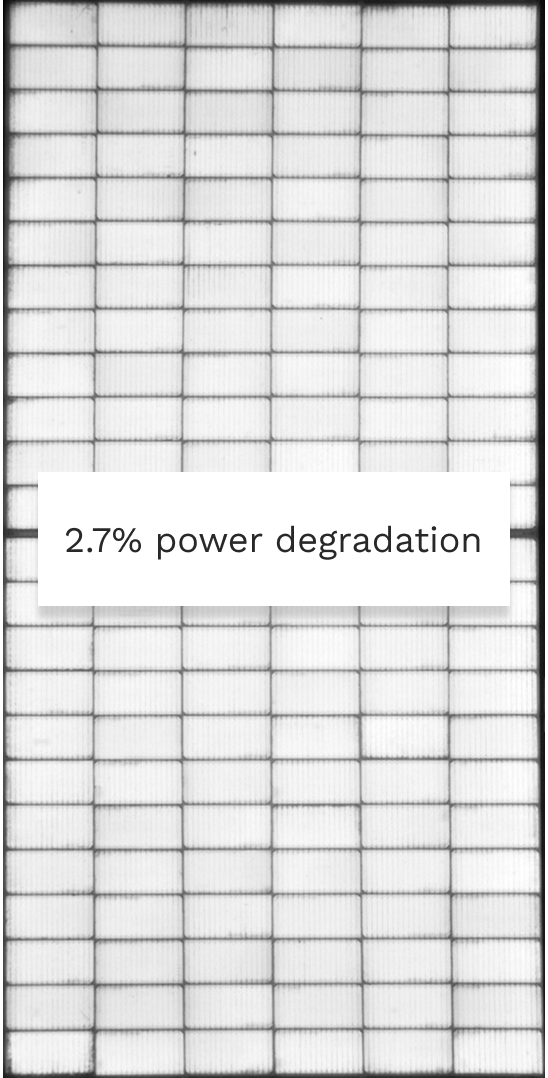

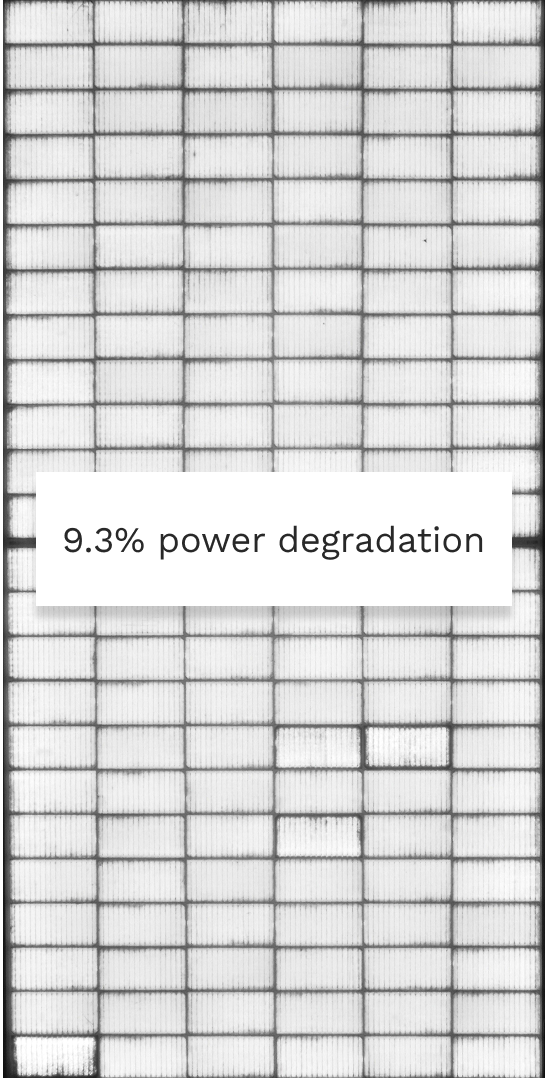

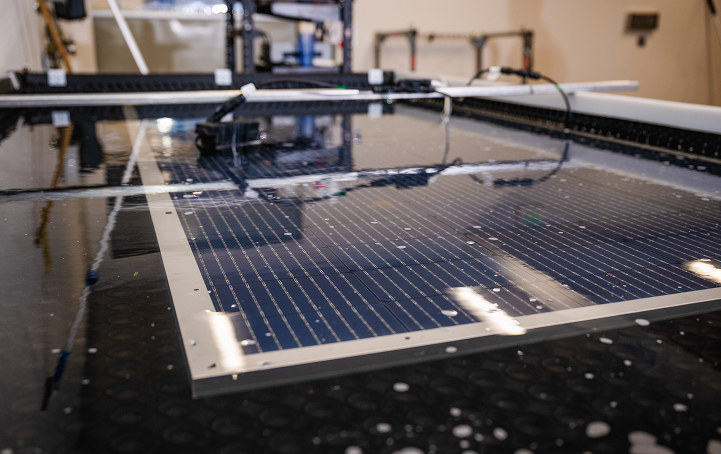

The initial EL image looks pristine, with no hint of what is to come following DH testing.

Key Takeaways

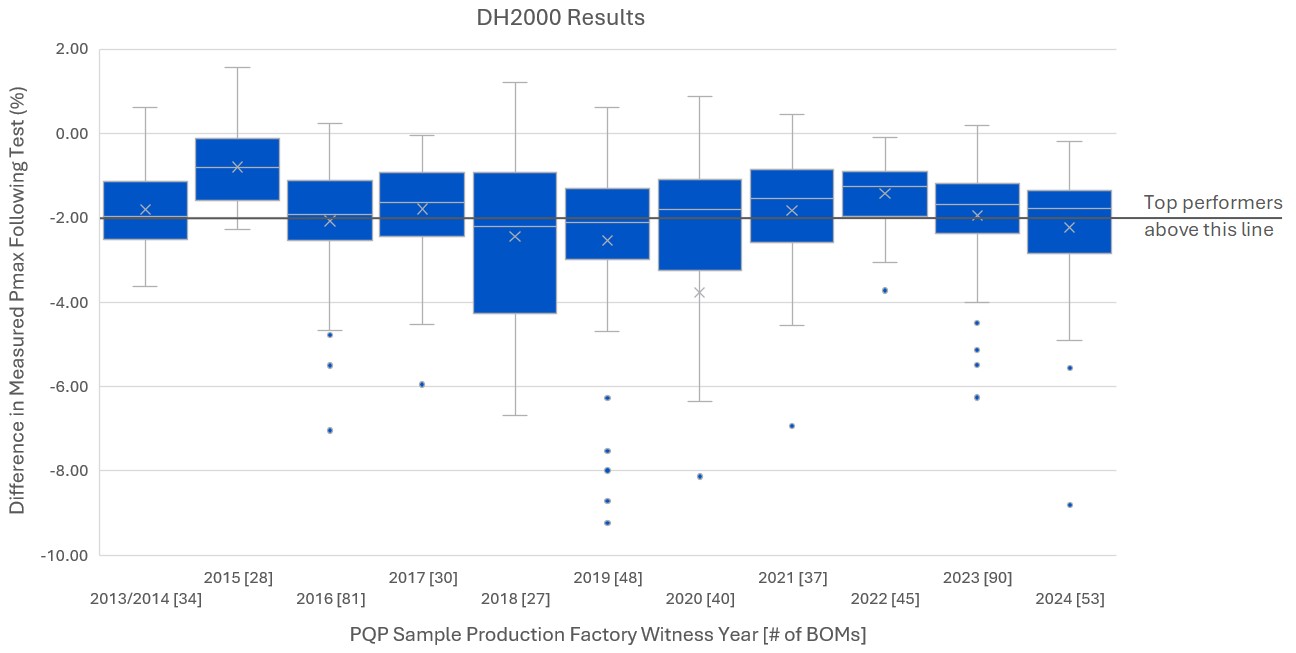

Fewer Top Performers

62% of BOMs tested degraded by < 2% following DH2000.

This has continued the decreasing trend from the 2024 and 2023 Scorecards, where 69% and 72% of BOMs had < 2% degradation, respectively. The median degradation for BOMs produced in 2024 was not significantly different from those produced in 2023, but BOMs from both years were lower than BOMs from 2022. See the Power Degradation graph below for more.

Cell Technology Impacts

TOPCon performed better than PERC; both better than HJT.

67% of TOPCon BOMs tested over the past year had degradation < 2% following DH. This dropped to 33% for PERC BOMs and 0% of HJT BOMs had < 2% degradation, but the sample sizes for PERC and HJT were significantly lower than TOPCon. There were some TOPCon outliers, including the maximum degradation recorded across all technologies: 8.8% from a TOPCon BOM.

Glass//Glass Advantages

For TOPCon BOMs, glass//glass had clear advantages over glass//backsheet.

The median power degradation for TOPCon glass//glass BOMs tested over the past year was 1.6% compared to 4.0% for TOPCon glass//backsheet BOMs. While this is encouraging for TOPCon BOMs, 9% of manufacturers experienced delamination failures along the edges of their glass//glass modules following DH testing, emphasizing the importance of proper lamination.

Failures Persist

10% of BOMs and 19% of manufacturers experienced one or more failures during DH testing.

These DH failures were due to delamination (as highlighted in the 2024 Scorecard), junction box lids falling off and power loss (see the Test Result Spotlight below). With increased diversification in cell design and encapsulation schemes, the number of failure modes has risen, including solder flux driven corrosion of busbars for some glass//glass modules. See the Failures page for more.

DH Test Result Spotlight

Both TOPCon and HJT cells are more susceptible to moisture-related corrosion than PERC, as has been observed in some DH test results over the past few years. That was the case here, where a glass//backsheet TOPCon BOM suffered corrosion-related power loss when moisture vapor entered the laminate through the backsheet. This can also occur with moisture vapor entering glass//glass laminates around the edges and through the junction box holes. While not all TOPCon BOMs suffer from this degradation mode, the choice of encapsulant, cell metallization, flux and backsheet (if applicable) are critical to ensure module reliability.

Power Degradation of DH BOMs

Percentage of results shown that are post-BO stabilization: 19% of 2018, 46% of 2019, 95% of 2020, 86% of 2021. All 2022 results and later are post-DH2000 (pre-BO stabilization), which is the stage in DH testing used to determine Top Performers for the 2025 Scorecard.

Outliers with >10% degradation are not shown. In some cases, these cause a significant reduction in the mean.