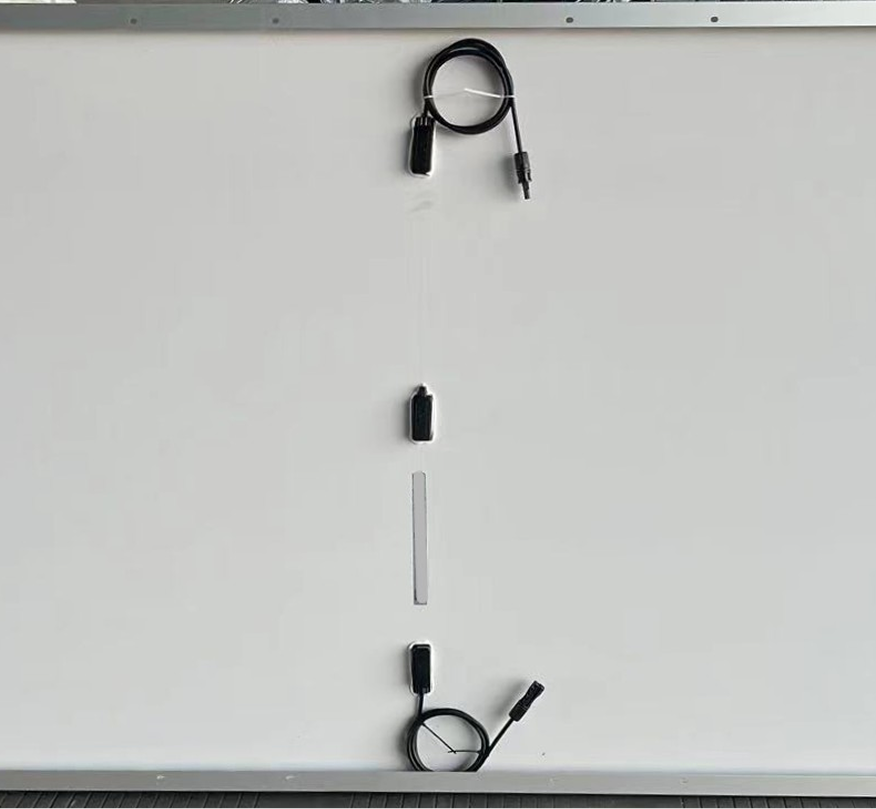

An image of a module from the same BOM, taken during the PQP sample production factory witness.

Key Takeaways

No Observed Cracking

Kiwa PVEL has not recorded any catastrophic failures during BDS testing.

Over the past two years, Kiwa PVEL’s BDS testing for PQPs has not revealed any backsheet cracking issues. This testing covers 25 BOMs with a range of outer layer materials including CPC, PVF, PVDF and PET films. The backsheets were transparent, white and black. None of those tested exhibited backsheet cracks following BDS testing.

Visual Defects Persist

The BDS test can induce a variety of major and minor visual anomalies.

While no backsheet cracking has been observed, several modules suffered from other issues, including illegible labels (a major defect according to IEC), busbar discoloration on the rear side of bifacial modules, cable chalking, cracked connectors and backsheet discoloration. These defects may potentially compromise the module’s long-term performance and structural integrity.

Increased Transparent Backsheet

White backsheets have become far less prevalent in PQP testing.

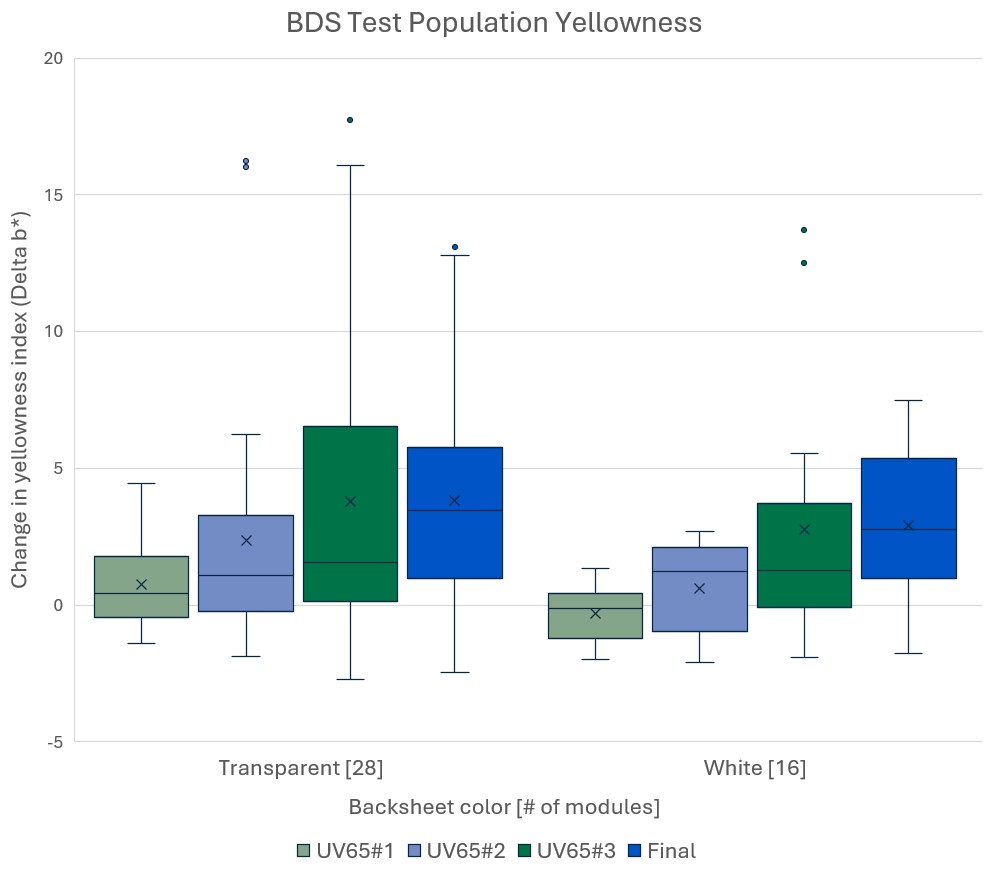

Bifacial modules with transparent backsheets comprise more than 56% of the test sample population in Kiwa PVEL’s BDS testing. Results show that transparent backsheets suffered from similar degradation and yellowing compared to white backsheets. See the Backsheet Yellowness Following BDS section below for more.

Reliability Risks Still Exist

Unproven backsheet formulations continue to emerge.

Many new module backsheets have been deployed in the field over the last few years, showing no early signs of degradation. It is possible that some of these unproven backsheets may reveal potential issues over the long term. BDS testing remains an essential step in validating backsheet reliability before deployment.

BDS Test Result Spotlight

A recently tested white backsheet BOM exhibited significant yellowness following the third round of UV exposure (i.e., following DH1000+UV65+TC50+HF10+UV65+TC50+HF10+UV65) when the delta b* spiked to greater than 13. Although increased yellowness does not always result in backsheet failure in the field, in some cases yellowing is an indicator of mechanical breakdown that leads to backsheet embrittlement and cracking in the field. When significant yellowness is seen in BDS testing, Kiwa PVEL recommends that the manufacturer provide additional evidence to prove the backsheet will perform reliably for the expected module lifetime.

Backsheet Yellowness Following BDS

During BDS testing, Kiwa PVEL performs colorimeter measurements at 10 different backsheet locations for two identical samples per BOM. The measurements use the Commission Internationale de l’Eclairage (CIE) L*a*b* coordinate system, with b* representing the yellow/blue coordinate. As yellowness index increases so does the b* value. BDS reports include a graph showing the average difference in b* values (“delta b star”) throughout BDS testing to help quantify the change in backsheet color. A broad range of delta b* values have been measured across transparent and white backsheets, indicating that some BOMs are more vulnerable to yellowing than others.

Over the past two years, completed BDS test results on 44 modules show a range of yellowness.