Our mission is to support the worldwide PV module market by generating data that accelerates adoption of solar technology. Start using the data behind PVEL’s Scorecards and Top Performer rankings to improve your PV module procurement.

Downstream Partners

Best Practices for Module Procurement

Researching top-performing PV modules is only one aspect of risk mitigation for solar PV assets. The Kiwa Group supports downstream project stakeholders at every step of project development, construction, and operation.

Below are Kiwa’s recommended best practices for module procurement:

Procure Top-Performing Bills of Materials

Each Top Performer listed in the Scorecard represents a unique bill of materials (BOM). PVEL supports its network of downstream partners with BOM information for the products we test. PVEL’s downstream partners use this data to specify BOMs in PV module supply agreements. Contact us to access test reports and BOM data for Top Performers.

Audit and Monitor Factories

Sophisticated module purchasers require factory audits, or independent inspections of a manufacturer’s production lines, before PV module procurement to ensure suppliers meet quality standards. Monitoring PV module production during the manufacturing process also helps prevent quality issues in the modules produced for a specific project and ensures that the PQP-tested BOM is being used. These services are performed by PI Berlin and others in the Kiwa Group.

Validate Quality

Testing statistically significant samples of PV modules during module production helps buyers identify and remedy quality issues in the modules being deployed to their sites. This process, known as batch testing, requires shipping a randomly selected subset of PV modules from the factory to PVEL or other Kiwa Group labs for assessment. This can also be performed via third party oversight in the manufacturer’s in-factory lab.

Verify Performance

Testing PV modules upon delivery to the project site and prior to system commissioning helps identify damage that has occurred during transportation or installation. PVEL and other Kiwa Group companies provide on-site testing for utility-scale solar projects across much of the globe. When performance or reliability issues arise in the field, PVEL and the Kiwa Group are available to diagnose problems and provide guidance for remediation.

Become a PVEL ‘Premium Partner.’

Subscribers to PVEL’s Premium Partner Program receive a quarterly spreadsheet of all PVEL PQP test results.

This allows for quickly benchmarking manufacturers and model types via the industry’s largest database of reliability and performance testing results (module manufacturers can opt-in to share their results, others are shared anonymously). Users can customize the pass/fail criteria to identify BOM combinations that meet your quality requirements.

Subscribers also receive other insights from PVEL’s experts on a quarterly basis. Contact us to subscribe as a Premium Partner.

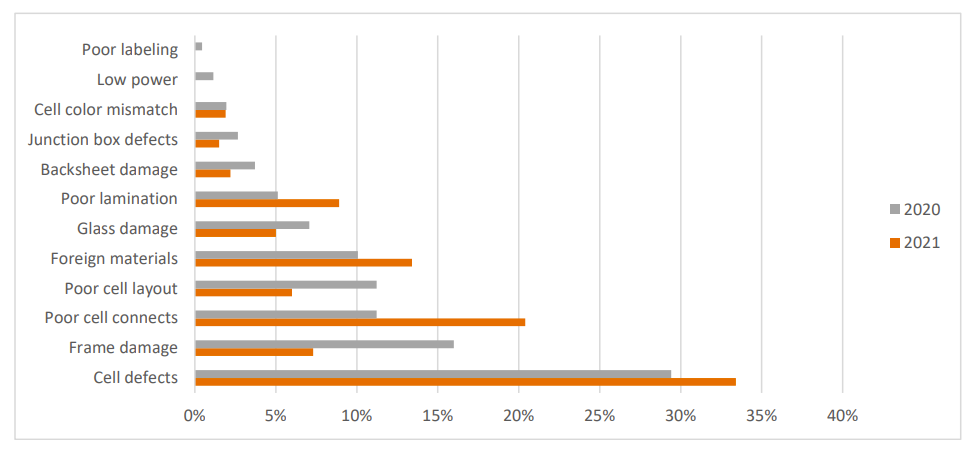

Factory Insights – PI Berlin Reports a Growing Trend in Cell Defects

In September 2022, PI Berlin, fellow member of the Kiwa Group, reported in their 2022 PV Module Quality Report that cell defects are the number one issue found during module production oversight. During the >8 GW of factory oversight conducted by PI Berlin in 2021, cell defects represented one third of all observed defects, an increase from the what was observed in 2020.

With the introduction of 182 and 210 mm wafers, most module manufacturers implemented radical overhauls of their manufacturing processes to accommodate the shift to larger cell sizes. This meant the installation of new manufacturing equipment, including cell stringing machines designed to handle cells of different sizes with more electrical interconnects. Furthering the production complexity, new cell cutting processes introduced more risks to cell damage if the cutting was inaccurate.

The major technological shift of larger cells, while clearly a benefit to the industry in the long-term, has also presented a new challenge to maintaining consistent module quality. PI Berlin deployment to factories on behalf of module purchasers helps to ensure these issues are identified and remedied.

For more on this and other factory insights, see PI Berlin’s 2022 PV Module Quality Report.